-

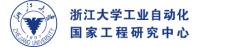

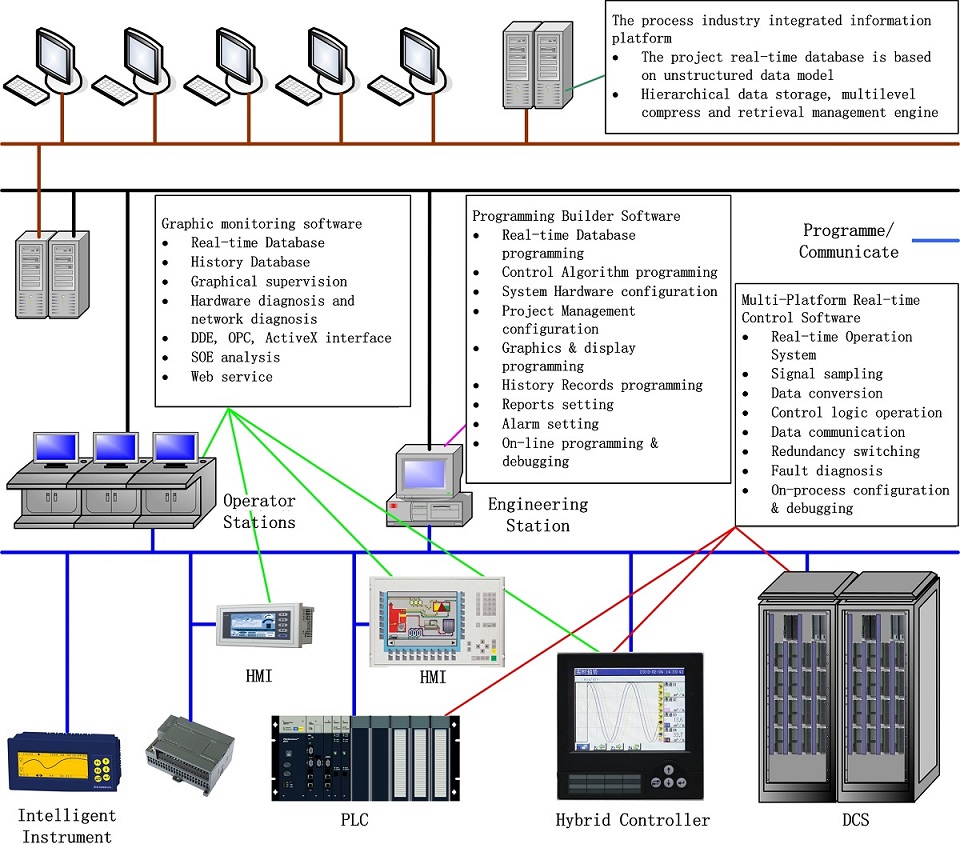

UWinTech control engineering application platform

The UWinTech control engineering application platform is based on multi-platform heterogeneous systems such as Windows 7 / Windows xp and real-time OS, adopting multitasking multithreading and component structure design, the collection of field data acquisition, the I/O module configuration module diagnosis, distributed real-time database, real-time control algorithm implementation, graphic monitoring and real-time operation, huge amounts of historical database, alarm and security mechanism, operating event log, engineering design document support and other functions in one. The engineer station programming configuration software, operator station graphics monitoring software, site control station real-time control software, run on different levels of hardware platform respectively, interacting various data , management and control information by controlling the network and system network, to complete various functions of the DCS coordinately.

More

-

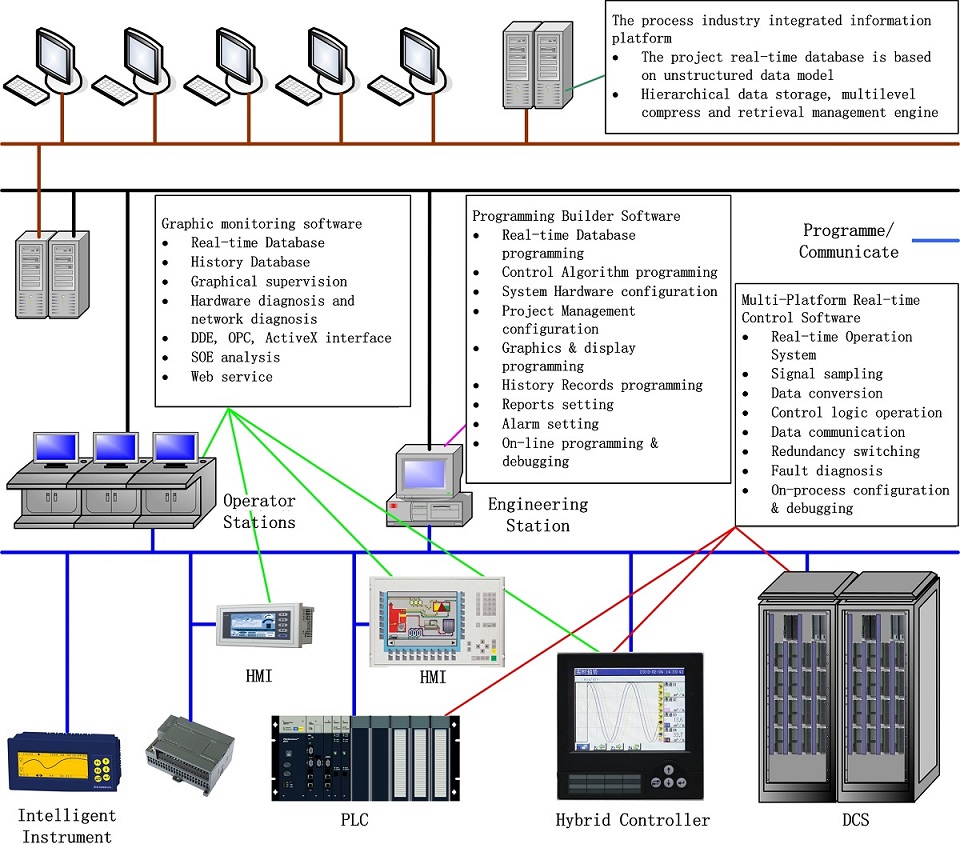

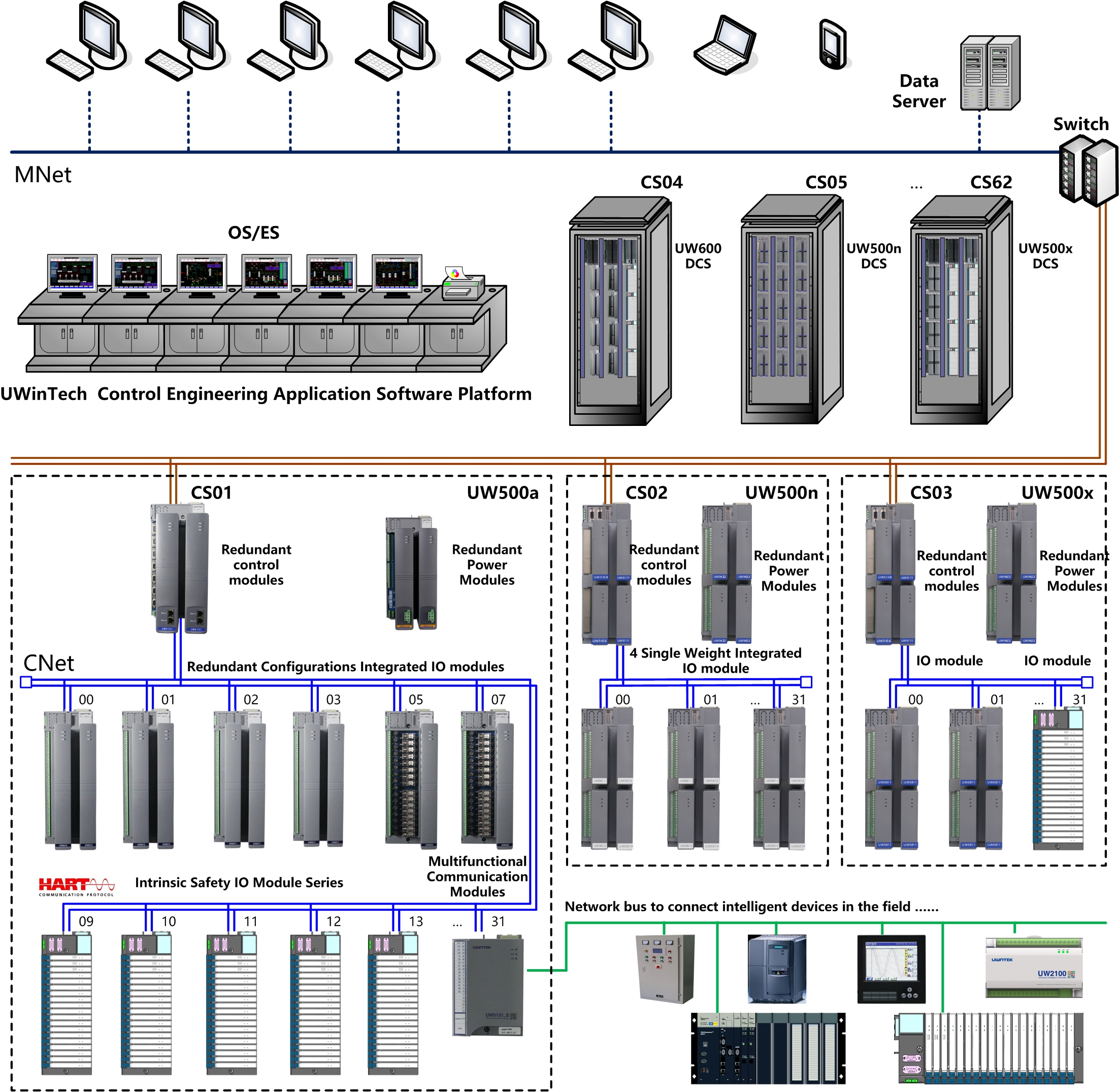

UW600 Distributed Control System

Depending upon the comprehensive technical ascendancies of Zhejiang University, absorbing decades’ academic and research state-of-the-art achievements of NERC ▪IA, State Key Laboratory of Industrial Control Technology and CSE, combining with our rich knowledge acquired in unremitting technology tackling and technical innovation as well as great experience in industrial application, after long-time and sustained application, improving, consummating and examining, we have successfully developed Excellent, Reliable, Advanced and Powerful Next-Generation Control System——UW600(UWinPAS600) Distributed Control System, which is marked by its High Reliability, Open System, Powerful Functions and Easy Maintenance. More than 1000 sets of products already widely applied in all industrial fields, encompassing Petroleum Chemical, Thermal Power, Nuclear Power, Steel-making, Chemical Industry, Construction, Light Industry, Paper-making, Environmental Protection and so on.

More

-

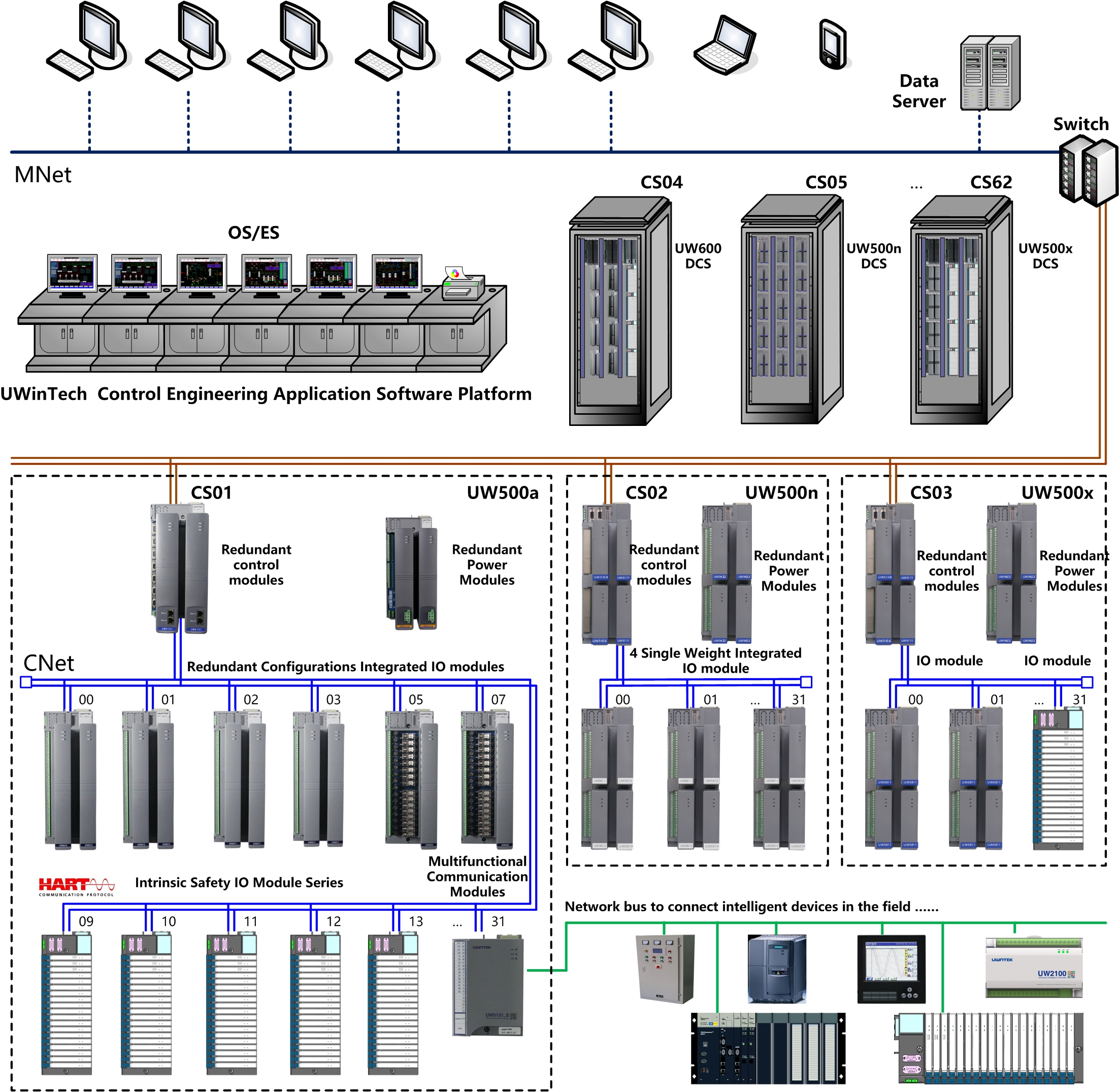

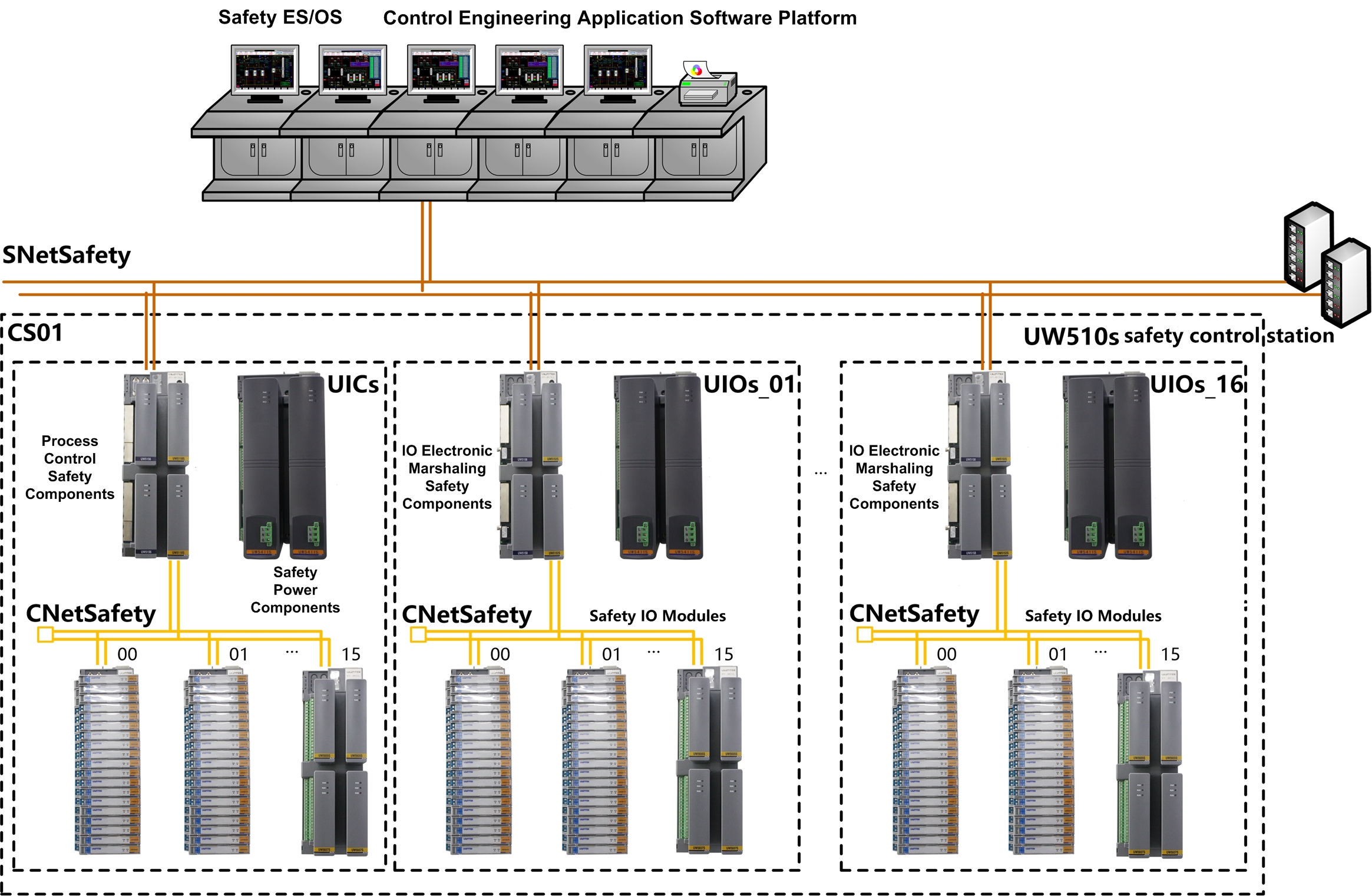

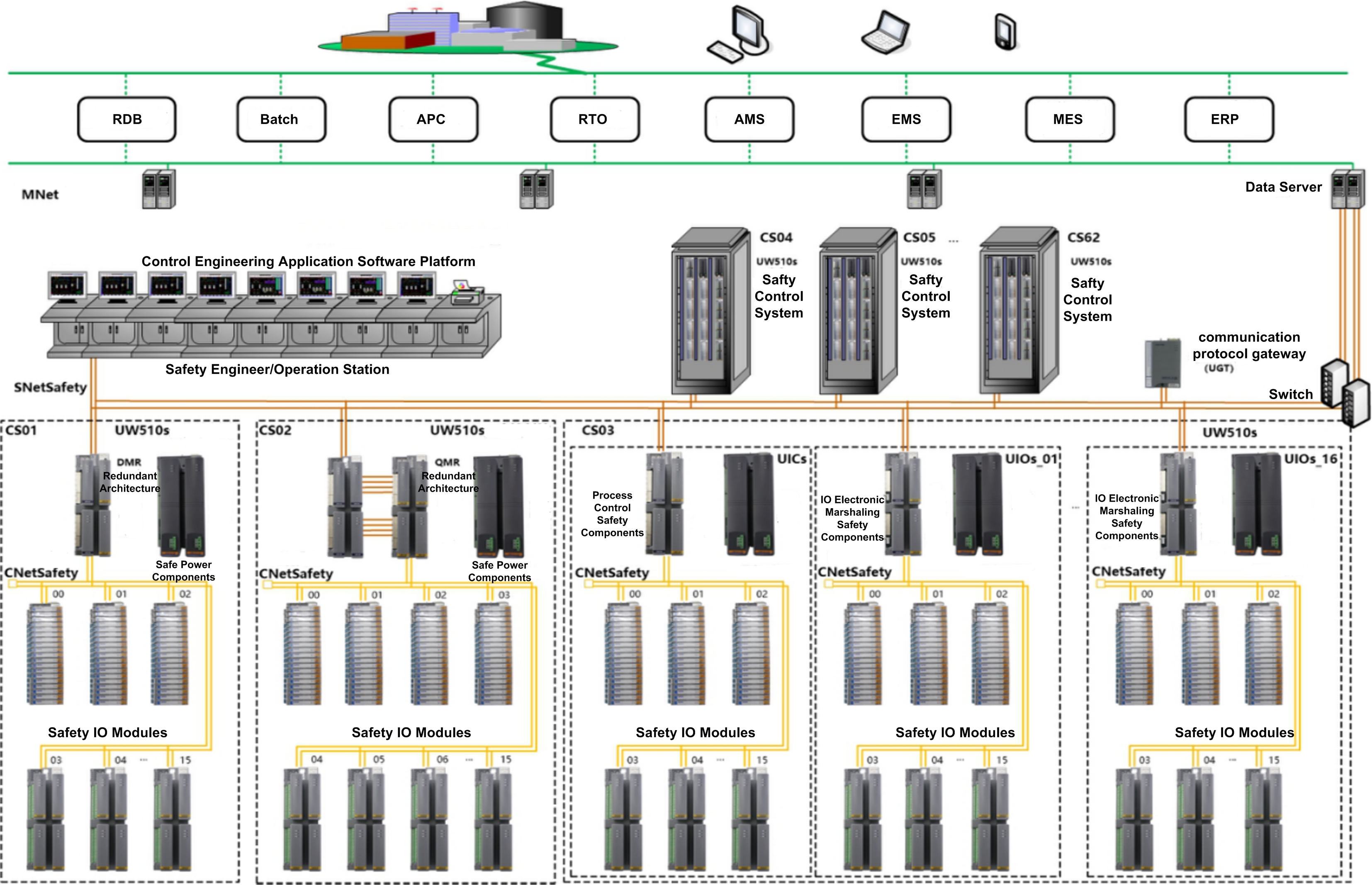

UW510s Safety Control System

UW510s(UWinPAS510s)is a Safety Control System with high safety, high reliability, and high adaptability specially developed for safety-related systems or demanding tasks. Its hardware devices adopt technologies such as hardware module redundancy and fault tolerance, high-availability safety modules, and high-safety industrial networks. The software platform adopts technologies such as multi-domain engineering object models, real-time control of safe operation, and endogenous safety active defense.

The Safety Control System consists of a safety control station, a programming monitoring computer and network equipment. the safety control station is composed of controller safety module, safety analog input module, safety analog output module, safety digital input module, safety digital output module, network switch module, power module and matching terminal block. It features high reliability, high availability, high safety, and high adaptability.

UW510s is suitable for safety-related applications in low-requirement and high-requirement modes defined by IEC61508, UW510s is suitable for FGS fire alarm and gas detection related applications as defined by EN 54-2 and NFPA 72. complies with SC3 system capability level and SIL3 hardware safety integrity level defined by IEC61508 and has passed SIL3 safety evaluation certification. The IO scale of local control station and electronic marshalling IO station:AIO:256、DIO:1024, the IO scale of system: AIO:15872、DIO:63488.

More

-

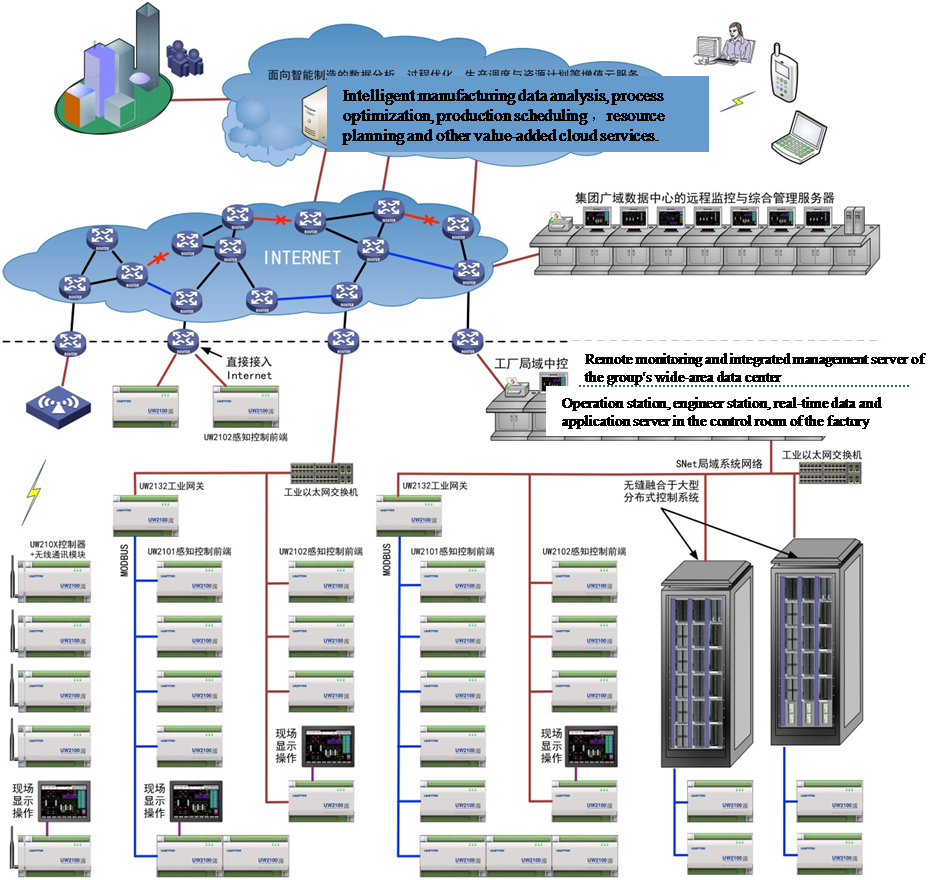

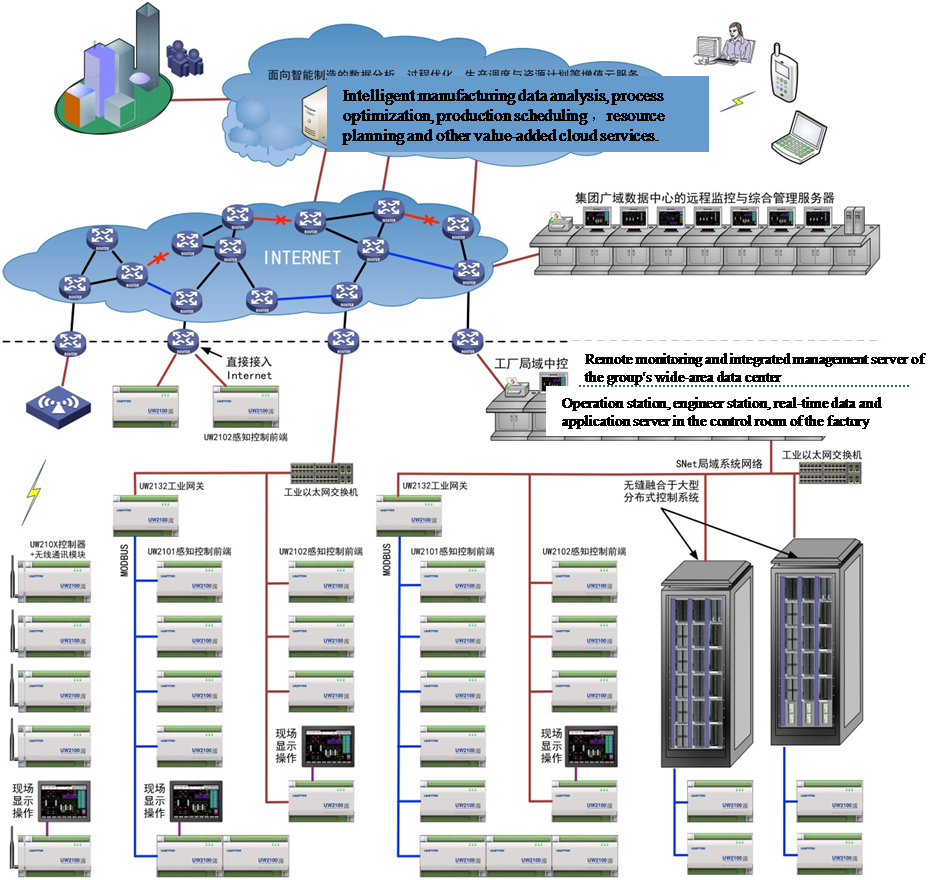

UW2100 Industrial Networking Control System

Depending upon the comprehensive technical ascendancies of Zhejiang University, absorbing decades’ academic and research state-of-the-art achievements of NERC ▪IA, State Key Laboratory of Industrial Control Technology and CSE, combining with our rich knowledge acquired in unremitting technology tackling and technical innovation as well as great experience in industrial application, to support the "intelligent manufacturing" national new strategic industry, based on the research and development of national 863 "high-end large-scale programmable automatic controller and system", the UW2100 industrial IOT control system eDCS has been successfully developed.

More

-

UW5100 Electronic Marshalling

The electronic wiring system is a new generation process control system that integrates software defined data link technology, software defined I/O technology, and optical communication replacement cable technology on the basis of existing DCS, achieving technological innovation and construction.

Software defined data link: Separate control module and I/O module, based on network technology and software defined technology, change the traditional static fixed connection mode between control module and I/O module, and achieve dynamic redistribution of data link;

Software definition of IO signal types: Software configuration enables input and output of multiple signals, achieving single channel signal isolation, type configuration, programmable amplification, data processing, fault diagnosis, filtering,linear correction, engineering conversion, etc., supporting online module replacement and signal type change without opening the box;

Optical communication replaces cable connection: The I/O module is located in front of the industrial site, where it is located. It achieves digital to analog and analog-to-digital conversion at the signal end, using advanced industrial AON optical network and TUV certified functional security protocol. Compared to civilian PON technology, it has leading communication fault tolerance and security, as well as high anti-interference and environmental adaptability.

More

-

OEM customized complete set of control devices

Depending on the comprehensive discipline advantages of Zhejiang university and the leading research results of National Engineering Research Center of industrial automation, Zhejiang University,based on the techonological accumulation of Focusing on intelligent instrument, programmable controller, distributed control system and control engineering application software platform of UWNTEK technical team in nearly ten years,and its OEM/ODM customized development and technical management, quality control and manufacturing management experience. Hangzhou UWNTEK automation system provide a number of OEM/ODM products customized development services, make customers' products unique, help customers sell their innovative products exclusively, create value added value for customers;

More